Contact us ?

Our shop and factory are located in 10 of ramadan, Egypt----the Industrial City of Egypt.

+ (20) 101 423 3111

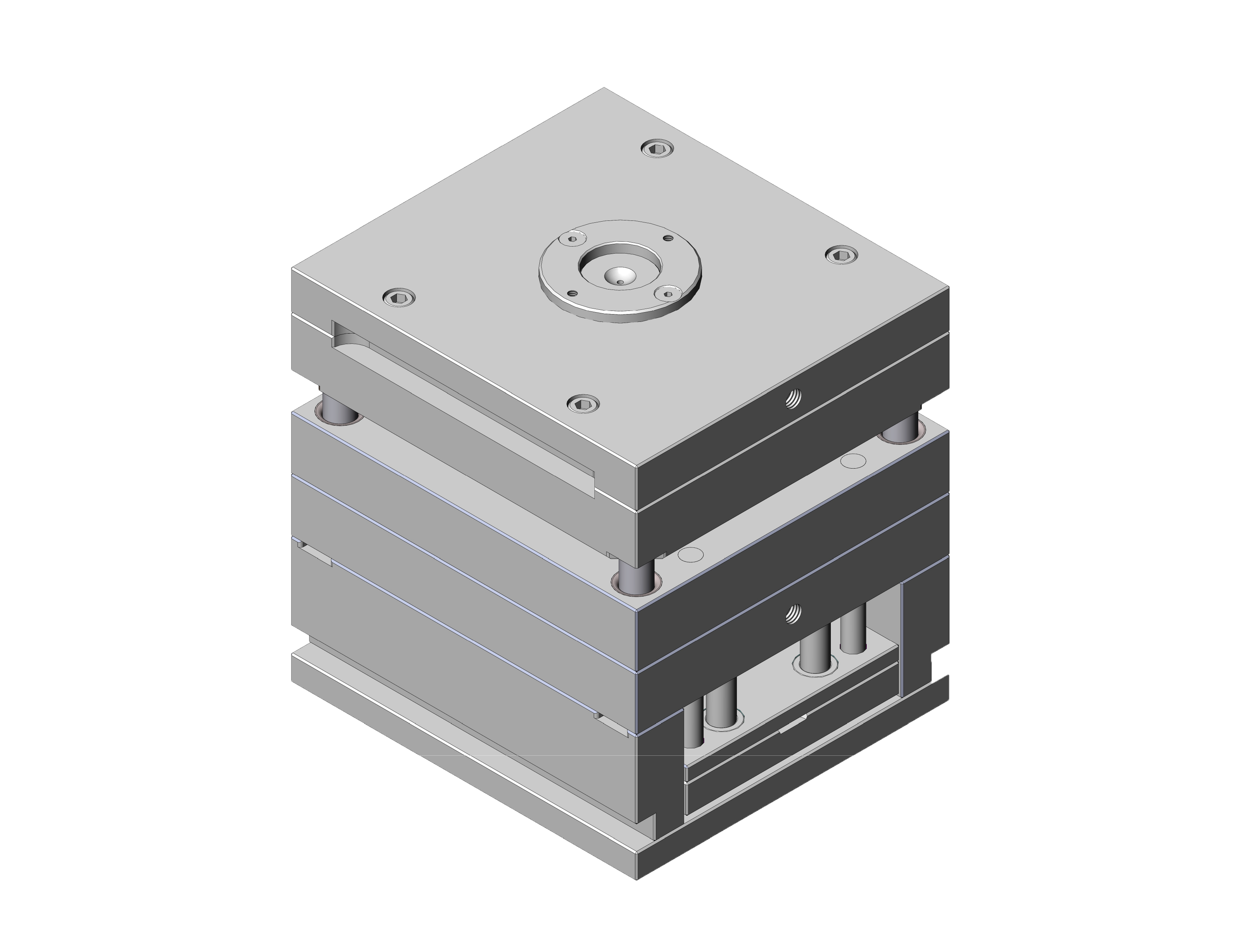

Mold Base

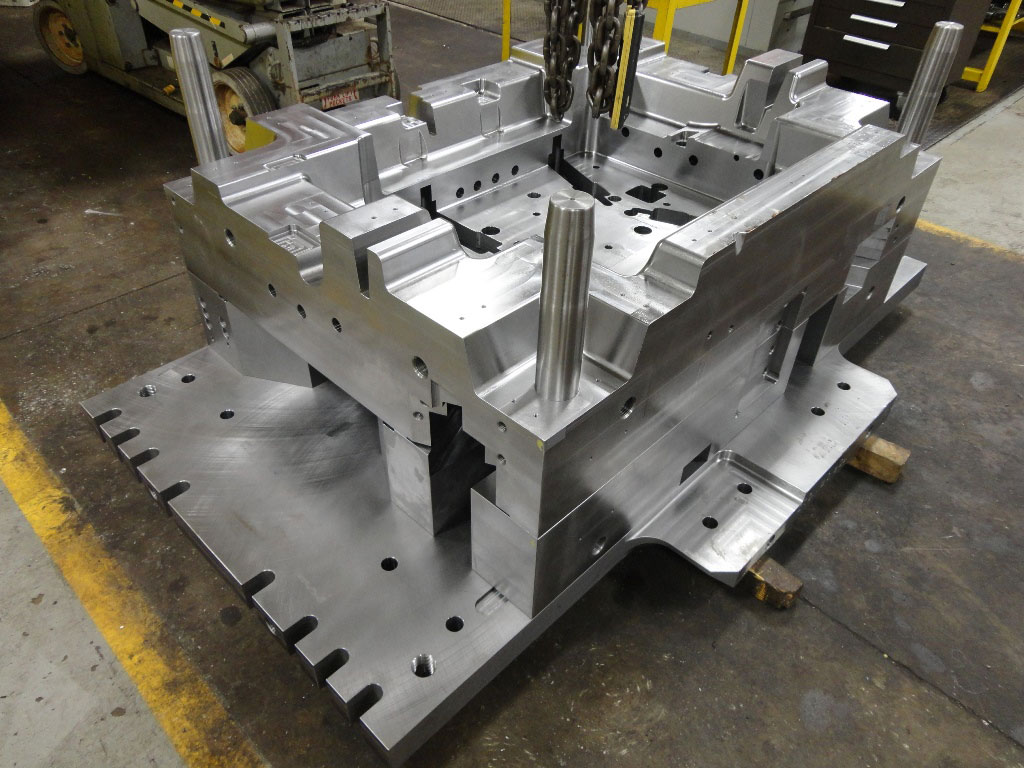

In injection molding, the mold core refers to a solid component that is used to create the internal features and cavities of a molded part. It is typically made of hardened steel and is separate from the mold cavity itself. Mold cores are used in conjunction with the mold cavity to form the complete shape of the molded part.

Lifter

The injection mold lifter is an essential component that makes the whole injection molding process successful. Why is that? Because the lifter is used at the final stage of producing plastics. This is when the molten plastic has been poured into the mold and is ready to be removed.

- Industrial Steel material

- Standard Mold base

- Suitable for general use

Mold inserts are irregular mold accessories implanted in the mold to attach the mold plate. Mold inserts do not comprise a fixed shape and structure, and they must usually be tailored by the actual mold construction, which has high precision requirements.

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time

What we can Do

Forming surfaces, slider bodies, guide pins, wedges, press blocks, and wear plates are the fundamental components that makeup slide mechanisms. Other common components include a pressing block. The injection mold slider is subject to wear and tear during normal operation.

Industrial profits grow faster with wangero

Place mold on steel plate and flat/labeled surface. Apply the oil (release agent) to the inside of the mold in order to easily remove the block.

We work to reduce air emissions associated with our operations

A mold base is an assembly of steel plates that contain the cores and cavities of a mold. The Mold Base feature creates a mold base from provided content libraries.

A brilliant record in responding to complex customer requirements.

The User Mold Base feature inserts a user defined Inventor assembly file. To use a file imported from another CAD system, save it as an Inventor assembly file before use.