Contact us ?

Our shop and factory are located in 10 of ramadan, Egypt----the Industrial City of Egypt.

+ (20) 101 423 3111

Hot Runner

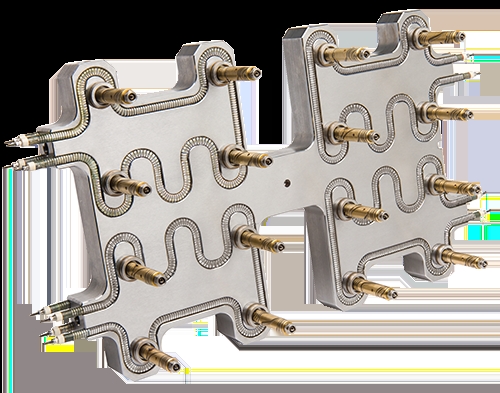

A Hot Runner System is used to maintain a molten flow of plastic from the molding machine nozzle to the gate of a plastic injection mold.In general the system is composed of three main parts; the sprue bush, the manifold block, and

one or more hot nozzles. The system can also include valve gates which are a method of physically shutting the gate off, allowing larger gates to be used while controlling the gate vestage.

Hot Runner System

When designing an injection mold the size and location of the gate is one of the most important considerations for correct molding of the part.

- Reduces cycle times.

- Reduces injection pressure.

- Improves part consistency and quality.

Hot runner technology, introduced to the plastics industry over 50 years ago, revolutionized injection molding processing capabilities by improving molded part quality, enhancing operational efficiencies, reducing scrap and saving money.

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time

What we can Do

A hot runner system is a molten plastic conveying unit used within an injection mold. In other words, a hot runner system consists of heated components (generally via electricity) used inside the plastic injection molds, which brings the molten plastic from the barrel of an injection molding machine into the cavities of the mold.

Industrial profits grow faster with wangero

Locating Ring – The locating ring aligns the injection mold with the platen of the molding machine. It ensures there is proper alignment of the mold with the machine.

We work to reduce air emissions associated with our operations

Inlet – When resin is injected into the mold, this is the entry port where the resin enters from the injection machine nozzle. Depending on the type of resin and the design of the hot runner the inlet component may be heated in order to optimize the molding process.

A brilliant record in responding to complex customer requirements.

Nozzles –Nozzles are components where the resin is injected into the cavity through a gate.Depending on the design, nozzles are typically installed into the mold plate with or without a manifold. A wide range of nozzle designs are available, using different materials, in order to achieve the processing characteristics of various resins that best suit the application.